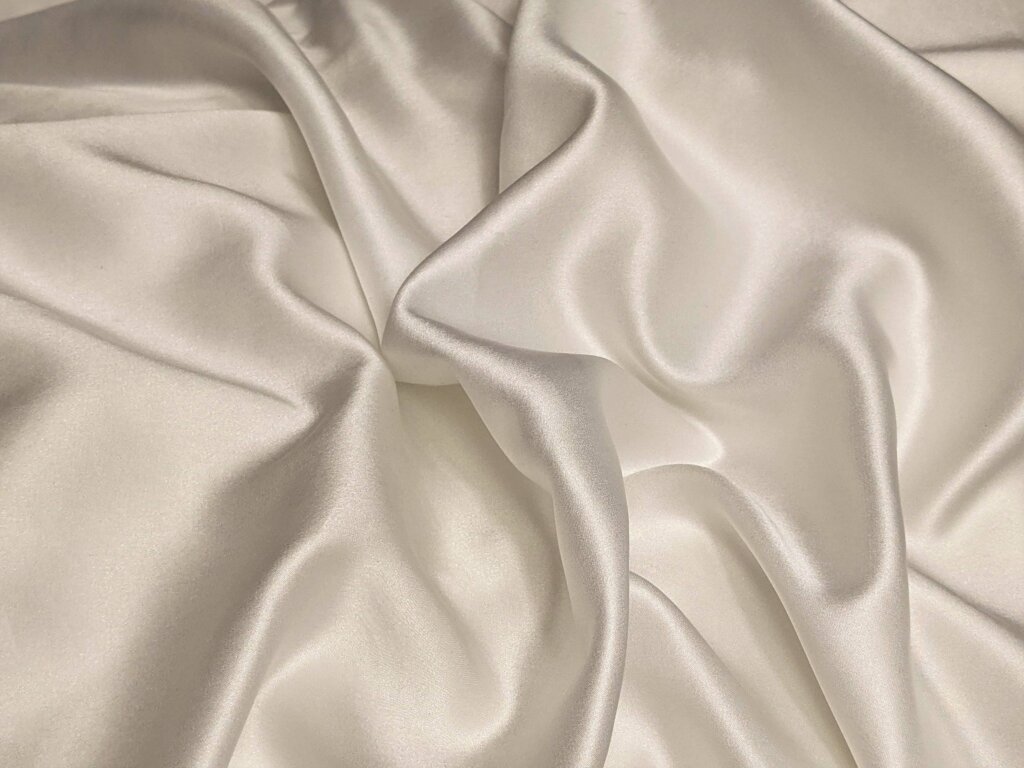

Viscose and rayon have a luxurious appearance and feel similar to that silk, and they can keep their vibrant hues over time. Its use dates back to the 19th century. Because it is manufactured from natural polymeric cellulose or regenerated cellulose, it falls into the category of “semi-synthetic fibers.” The term “viscose” is used to characterize the substance because of how it behaves in a spinning solution.

The viscose fabric known as rayon is derived from wood pulp and is commonly used as a cheaper alternative to silk. Artificial silk, or viscose, was first manufactured in 1883. Production costs are low, and it finds widespread application in the apparel and home decor industries.

Characteristics Of Viscose Fabric

Cellulosic base gives viscose properties many of the same qualities as cotton or other natural fibres made of cellulosic materials.

Here are some things about viscos fabric:

- Moisture absorbent (more than cotton)

- Breathable

- It’s easy to wear.

- Easy to colour in bright shades

- Skin-friendly

- Moderate strength and wear resistance when dry

- It can handle ironing temperatures just a little lower than cotton can

- It doesn’t bounce back like other cellulosic fibers, so it will wrinkle

Static electricity doesn’t build up on it, and it won’t pill unless the fabric is made of short, low-twist yarns. Silverfish and termites may try to eat it, but most insects don’t hurt it. It will mildew, but that’s not usually a big deal.

One of the best things about rayon is that it can be used in a lot of different ways and is easy to mix with other fibers, sometimes to cut costs and sometimes to add shine, softness, absorbency, and comfort. Rayon isn’t very resistant to acids and alkalis, and bleaches usually don’t hurt the fiber itself.

However, the dyes used in the fabric may change color. As a cellulosic fiber, rayon can catch fire, but it can be treated to make it less likely to do so.

Production Of Viscose

- Ageing

It adds to the thickness of viscose. Pulp from pine, spruce, or hemlock trees is mixed with caustic soda and left to steep for a certain amount of time. After that, the pulp is shredded and left to age. The more time it has to age, the less viscous it will be.

- Viscose formation Stage

Then, the old pulp is treated with carbon disulfide to make orange-colored cellulose xanthate, which is dissolved in less concentrated caustic soda. During the process, alkaline cellulose is mixed with an acetate dope, which is needed to make the yarn shiny.

- Regeneration Of Cellulose Fiber

A soluble compound is made from cellulose that has been cleaned. By passing a solution of this compound through the spinneret, soft filaments are made. These filaments are then “regenerated” into almost pure cellulose.

Types Of Viscose Fibers

Today, various distinct kinds of rayon fiber are produced and sold to the general public. Their names reflect the methodology used to dissolve cellulose before regenerating it. The following are the most common types of Viscose fibers:

- Nitrocellulose

This is the first kind of viscose. It was invented in 1855 and called “artificial silk” or viscose silk. It was first made for sale in 1891. Nitrocellulose rayon was very easy to catch on fire and was expensive to make, so it stopped being made in the early 1900s.

- Acetate

Acetate used to be called rayon because it is made from the same material as rayon, which is cellulose. Acetate fabric is no longer made because it was found that rayon was stronger than acetate.

- Cuprammonium Rayon

In the past, textile makers began to use cuprammonium rayon. With the development of new ways to make rayon, cuprammonium rayon stopped being made.

- Lyocell

Lyocell is different from rayon in the way it is made. But these two materials feel and last almost exactly the same, and lyocell is often thought of as a type of rayon.

- Modal

This type of viscose material is made by spinning cellulose from trees that have been reformed. Modal viscose/rayon has less pilling than cotton and is stronger and more tensile than regular viscose. It is often used with viscose cotton and spandex to make clothes and other things for the home.

Factors Involved In Engineering Properties Of Viscose

When engineering the properties of different viscose, the following factors need to be taken into consideration.

- Degree Of Polymerization (DP)

The stronger the fiber, the higher the DP, and a low acid concentration in the spinning dope will slow the rate of coagulation.

In order to optimize the physical properties of the polymer, it is desirable to use zinc-free dope in combination with modifiers that will extend the gel state length during spinning. This will allow for the application of a high viscose fabric stretchy through the orientation of the polymer chains.

- Semi-Continuous Process

All of them are made of yarns that are wet spun and made in a semi-continuous process. Wet spun means that the threads that come out of the spinneret go straight into chemical baths to harden or be regenerated. All of the early production of viscose material was done in batches. Processes have been changed in recent years so that production can go on in a semi-continuous way.

Applications Of Viscose

After its discovery in 1891, viscose rayon remained a niche product for quite some time, utilized mostly for ornamental uses such as fake flowers and garment trimmings.

In later years, it largely supplanted or was used with mercerized cotton yarns when making embroidered goods and stockings. Tie making, children’s clothing, hoods, tablecloths, socks, shoes, and decorative bags were among common uses (Woodhouse, 1926).

Because of its affordability, durability, and softness, viscos material has replaced cotton in many modern applications. This is notably true in the garment, value-added application, and domestic item industries. In fact, industrial textiles have found a use for even high-tenacity rayon.

- Yarns

Static electricity won’t build up, and it won’t pill unless the yarn is made of short staples with a low twist, which is why it’s best for sewing thread. Since it is easy to dye in bright colors, it is used as embroidery thread, chenille, cord, and novelty yarn.

- Apparel

Viscose clothing is a soft and comfortable fabric. It hangs well, which is one reason why it is so popular as a fabric for clothes. So, it is often used to make blouses, dresses, saris, jackets, lingerie, linings, millinery (hats), slacks, sports shirts, sportswear, suits, ties, and work clothes.

- Fabrics

Rayon is the most absorbent cellulose fiber, even more so than cotton and linen. Because of this, rayon soaks up sweat and lets it evaporate away from the skin, making it a great viscose blend fabric for the summer. It soaks up dyes just as well as it does water, so it can make beautiful, deep, rich colors. So, crepe, gabardine, suiting, lace, fabrics for outerwear, and the linings of fur coats are more likely to be made from it.

- Domestic Textiles

Viscose clothes fabrics look and feel like viscose silk fabric. Used for bedspreads, blankets, curtains, draperies, sheets, slipcovers, tablecloths, and upholstery, among other things.

- Industrial Fabric

High-tenacity rayon is used to reinforce rubber products like tires, conveyor belts, and hoses. It is also used in braided cords and tapes, as well as in the aerospace, agricultural, and textile industries. It is also used to make products for medical surgery, nonwoven products, tire cord, and other things.

- Other

Rayon is one of the main things used to make carbon fiber.

Even though material viscose has a lot of viscose benefits, but it is hard to work with because of its moderate dry strength, low pill resistance, and low abrasion resistance, as well as its poor wet strength.

Although rayon fiber is made of smooth, inelastic filaments like glass rods, this makes it slippery and hard to work with until it is sized or twisted very tightly. Aside from that, it is very hard to knot with a shuttle eye or needle. All of these things make it harder to process. It can also be used directly as clothing because of how shiny it is.

Limitations Of Viscose

There have been many attempts to get around these problems in the past.

Cut staple spinning of continuous filament yarns by ring spinning, either as 100% viscose blend or as a mix, is the best way to do this.

Even though these yarns get around the problems listed above, they still have to be made a long way. The time it takes to make something and how much it costs to go up when the process takes longer.

But texturing is another option:

- It changes a structure that is flat, round, and slippery into one that is wrinkly or loopy and holds its parts together well.

- It changes the glass-rod-like structure of continuous filament yarn so that it looks like ring-spun yarn but is bulkier and fuller. This is done without cutting the yarn into staple fibers.

- During texturizing, crimps, curls, and loops create an uneven surface that makes it less shiny.

- Bound ingredients make the mixture more stable, stop it from sticking together, and make it less likely to slip because it has more grip.

- The only other difference is that this exercise is done in one step right after wet spinning.

So, adding texture to viscose fabric can help get rid of most of its problems in a cheap and quick way.

But viscose material isn’t thermoplastic, and it doesn’t hold its shape very well when it gets wet. This makes it hard to texture.

Is Viscose Polyester?

Many people are unsure whether it is viscose polyester, but there is a slight difference between viscose and polyster.

Long fibres are used to create both polyester and viscose, however polyester is a synthetic material while viscose is only semi-synthetic because it is formed from natural fibres that have been chemically altered. While viscose is more absorbent than polyester, polyester is better at wicking away moisture. Polyester is more convenient because it dries quickly and doesn’t wrinkle like viscous fabric does.

How Can We Recycle Viscose?

Even though its production has a significant ecological footprint, viscose may be broken down naturally. The method is effective only with garments constructed entirely of natural fibers like cotton. Viscose is a biodegradable material derived from wood cellulose, but its breakdown also releases chemicals employed in its manufacturing.

Because of mass production, the fashion business leaves a larger imprint than necessary on the environment. It’s unthinkable that major fashion houses would start recycling their old inventory as compost.