If you’re starting a clothing brand or printing your own designs, one of your biggest decisions is choosing between DTG printing and screen printing.

Both are popular in the fashion industry — from streetwear brands to custom hoodie manufacturers — but each offers different advantages depending on your order size, fabric type, and budget.

In this complete guide from Tack Apparel, we’ll break down everything you need to know to choose the best printing method for your next collection.

What Is DTG (Direct-to-Garment) Printing?

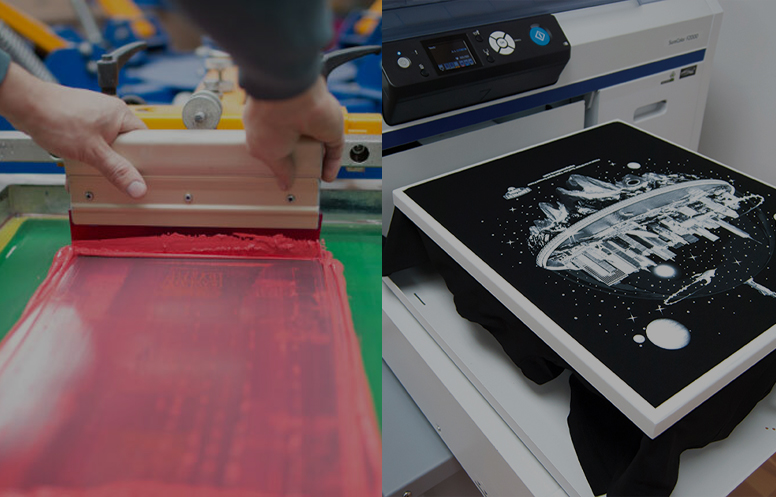

DTG printing is a modern, digital printing technique that applies water-based ink directly onto the garment using a high-tech printer.

It’s perfect for detailed artwork, small batches, and full-color designs.

How DTG Works

-

The fabric (usually cotton) is pre-treated.

-

A digital printer sprays ink directly onto the fabric.

-

The garment is heat-cured for lasting color.

Best For

-

Small orders or limited drops

-

Full-color or photo-realistic designs

-

100% cotton t-shirts and hoodies

Pros of DTG Printing

- No setup costs (ideal for small brands)

- High-detail printing (photos, gradients, complex art)

- Eco-friendly, water-based inks

- Fast turnaround for small runs

Cons

- Not ideal for large bulk orders

- Works best on cotton

- Slightly less durable than screen prints for heavy wear

What Is Screen Printing?

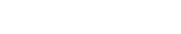

Screen printing, also known as silkscreen printing, is a classic technique where ink is pushed through mesh screens onto fabric.

Each color in your design needs a separate screen, making it better suited for bulk production.

How Screen Printing Works

-

A stencil (screen) is made for each color.

-

Ink is applied layer by layer.

-

The garment is heat-cured for long-lasting print quality.

Best For

-

Large production runs (50+ pieces)

-

Simple logo designs

-

Streetwear and promotional apparel

Pros of Screen Printing

- Extremely durable prints

- Cost-effective for large runs

- Works on many fabrics (cotton, polyester, blends)

Cons

- Higher setup cost

- Limited color detail

- Slower setup for small orders

DTG vs Screen Printing: Comparison Table

| Feature | DTG Printing | Screen Printing |

|---|---|---|

| Setup Cost | Low | High |

| Best For | Small batches | Bulk orders |

| Detail Quality | Excellent | Moderate |

| Durability | Good | Excellent |

| Fabric Type | Cotton | Cotton & blends |

| Eco-Friendly | High | Moderate |

Which Should You Choose?

- Choose DTG printing if you’re a startup streetwear brand, testing designs, or printing small orders.

- Choose screen printing if you’re running large production or need long-lasting prints for hoodies, uniforms, or events.

Pro Tip: Many successful brands use both — DTG for small drops and screen printing for mass production.

Printing for Streetwear Brands

In the streetwear industry, your print quality defines your brand.

DTG is perfect for limited-edition hoodies and detailed graphics, while screen printing delivers that bold, classic streetwear look for mass production.

If you’re serious about building a fashion brand, it’s worth learning both methods and partnering with a trusted clothing manufacturer like Tack Apparel.

Work With a Professional Clothing Manufacturer

At Tack Apparel, we specialize in custom clothing manufacturing, DTG printing, and screen printing for streetwear, fitness, and lifestyle brands.

We help you create:

- Custom hoodies, t-shirts, and joggers

- Fully branded streetwear collections

- Small-batch samples or bulk production runs

Learn: How to Start a Clothing Line

Why Choose Tack Apparel

- Full-service apparel production (design, sourcing, printing, packaging)

- No MOQ options for small brands

- USA-based quality control

- Fast turnaround and reliable communication

Whether you’re a new streetwear startup or an established fashion label, we make production easy and affordable.

FAQs: DTG vs Screen Printing

1. Is DTG better than screen printing?

DTG is better for small runs, detailed designs, and print-on-demand businesses. Screen printing is best for bulk orders and long-lasting prints.

2. Does DTG printing fade over time?

With proper care (cold wash, inside-out), DTG prints can last for years, though screen printing remains more durable for heavy use.

3. Can you combine both methods?

Yes! Many brands use DTG for samples or test drops and switch to screen printing once demand increases.

4. Which is more cost-effective?

Screen printing wins for bulk orders, but DTG saves money for small quantities or custom pieces.

Final Thoughts

Whether you choose DTG printing or screen printing, the goal is the same — create apparel that represents your brand with professional quality.

At Tack Apparel, we help you decide which method fits your fabric, budget, and brand vision.

Ready to bring your designs to life?